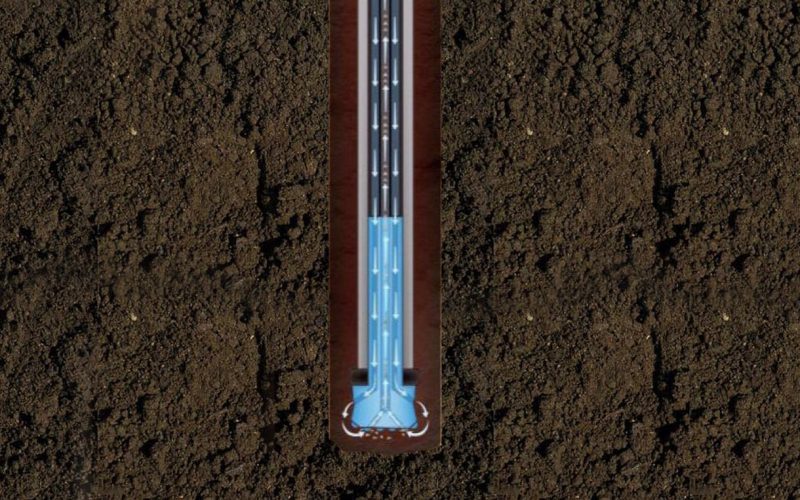

Reverse Circulation, or RC Drilling, is a clean and environmentally friendly method of deep foundation installation. It employs dual-wall drill rods, comprised of an outer drill rod with an inner tube (Figure 1). As the sections of drill rod are screwed together, the inner tubes overlap and seal with O rings. This provides a continuous path for the drill tailings to be transported from the bit face to the surface.

During the drilling process, high pressure air is introduced to the annulus between the inner tube and the outer rod. The air flows through the drill steel and powers the drill tool. As the air exhausts, it serves as a circulating medium by carrying the cuttings from the surface of the bit directly through the inside of the drill steel (Figure 2). As it exits the top of the drill stack, the air is guided into a cyclone which slows the cuttings, separates them from the air and collects them while the remainder of the waste fluids are captured in an isolated, watertight containment bin. The material is stored in this bin until it can be scooped out and disposed of off-site.