Sheet pile walls are used as an earth retention system in soils that allow driving from the surface to a termination depth. They do not work well in soil conditions with boulders or large obstructions. Sheet piles are pre-fabricated steel sheet sections with interlocking edges. As the sheets are installed, they form a continuous barrier in the ground. The sheets are typically driven with vibratory hammers or drop hammers.

Sheet piles can be arranged into geometric shapes to form cofferdams, allowing permanent in-ground construction to take place, such as a pier foundation in the middle of a river.

Sheet pile retaining walls and cofferdams are usually restrained with steel bracing, soldier piles, anchors and deadmen.

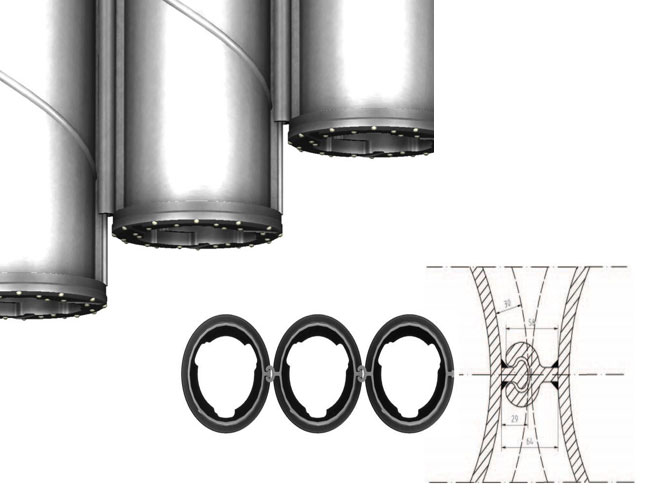

O-piles

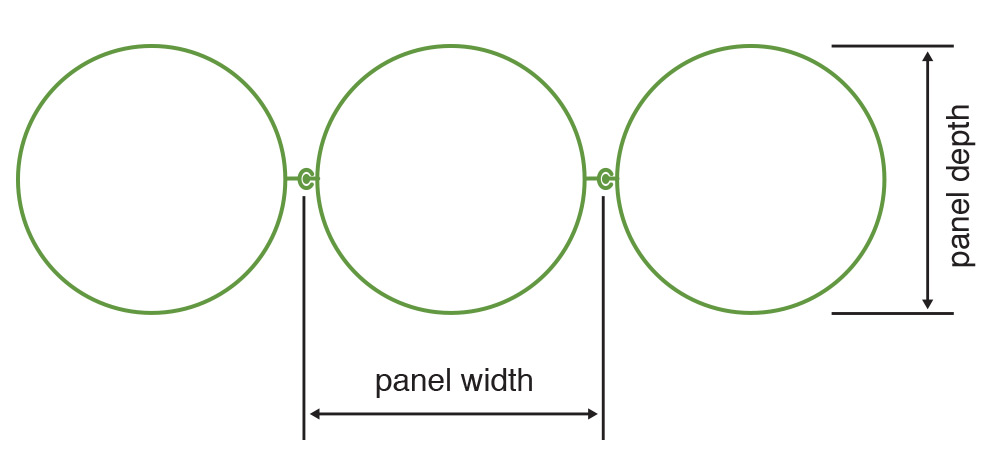

Interlocking O-pile walls are a relatively new retention system. They are made up of interlocking steel pipe with welded interlocking connections that thread into one another. They can be drilled in any ground conditions utilizing a down-hole hammer. Their application is the same as for sheet piles, but with the added benefit of being able to advance through challenging geotechnical formations (e.g. soil with boulders or other obstructions), and the ability to be founded into bed rock.

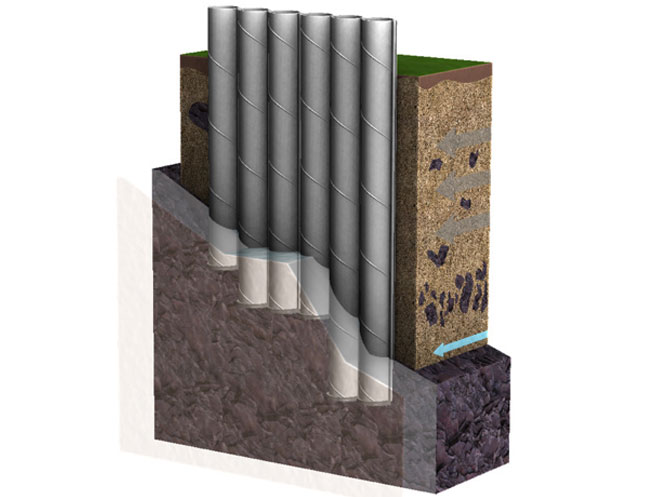

O-PILE APPLICATION

Many projects are designed using driven sheet piles. For some of these projects there is a better solution. The big problem with sheet piling is the inability to penetrate tough conditions and embed them into bedrock. This is where O-pile becomes a more practical solution.

Unlike sheet piles that cannot penetrate bedrock, drilled O-Piles can be installed and embedded into the hardest of rock formations, allowing design engineers the ability to design walls that are guaranteed to achieve design depth. The O-Pile also allows for grouting either the rock portion or the entire pile length to ensure water tight connection.

Since the connectors are welded onto standard pipe, the system can accommodate any shape of wall. Boxes, curved walls or sharp corners are no problem.

Once the first pile is drilled with care for accuracy, the following piles are easy to keep in alignment. Nice straight walls are easily achieved.